Ad for a machine made quilt 1940

In 1895 several newspapers ran a lengthy story about commercial quiltmaking in Connecticut, which began with a tale about cottage industries where local women quilted for an entrepreneur who peddled their needlework to retail and wholesale customers. Industry histories always treat the facts loosely but this sounds reasonable---if vague.

"About 1874 this business originated....quilt materials were stored, to be distributed among the farmers' wives of the vicinity, who occupied their leisure hours between the regular 12 o'clock dinner and 6 o'clock tea, as well as the long winter evenings, in quilting for the manufacturers, who repaid their labor by the munificent sum of 12-1/2 cents for each finished quilt."

Were the women workers hand quilting or machine quilting?

"When a sufficient number of quilts were completed the manufacturer started upon the road with his stock, peddling his goods alike to house and store keepers. As his trade increased, quarters were prepared for the workers within the storehouse, which then really became a factory, where eventually the quilts began to run by ordinary sewing machines. A year or two later the business had increased...a large stone factory was built, power machines superseded the old-style ones...and three or four hundred boxes and bales of a dozen quilts each were shipped....700 quilts daily."

The article goes on to talk about production.

"The quilting machines are tended by girls, who are paid two and a half cents for each quilt, and forty quilts are considered an average day's work. Some of the girls make $7 a week....

In 1884 a new machine for quilting was invented...The quilt is stretched in a wooden frame and stitched in the most intricate designs by power....The designs are frequently interlaced, mingled, and multiplied upon the same surface until the result is an arabesque of great regularity and attractiveness."

I would guess that the unnamed factory was one of the Palmer Brothers Bedquilt Manufacturers in Fitchville, New London or Montville, Connecticut. From a late-20th-century Fitchville history:

"Edward and Elisha Palmer copied the designs from the beautiful quilts Elisha's daughter was making....George Palmer originally designed and patented the machines that were used to sew the quilts. The quilts were made in many

different designs and colors. The Palmers became world famous

for these unique heavy warm quilts."

Elisha had two daughters, Arabelle Palmer Latimer (1849-1928) and Mary Alice Palmer Mitchell (1847-?). (Mary Alice's DAR number is 66475.)

The Palmer Brothers purchased a mill in Fitchville, New London

in 1886. This complex burned in the 1960s and '70s.

The Palmer mills continued manufacturing quilts well into the 20th century.

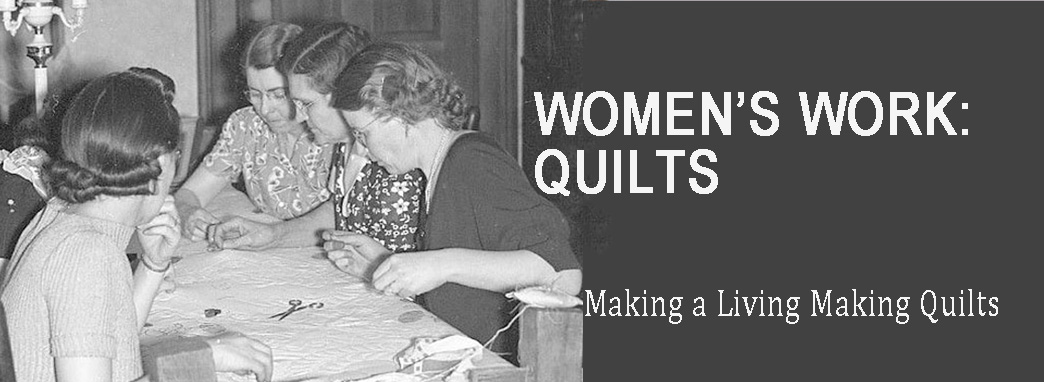

Library of Congress

When the housing was photographed in the 1930s the

factory was making comforters for the army.

Giant quilting machines

In 1941 you could buy Palmer Patch Bedquilts at Quackenbush's in Paterson, New Jersey.

Or at Snellenburg's in Bristol, Pennsylvania in December, 1942.

We get a clue to as one kind of Palmer Bros. bedquilt:

Wholecloth sateen with wool batting?

The company disbanded in 1948.

Read more about those Connecticut quilt mills in Jon B. Chase's book Montville. See a Google Preview here: